Is a Constant Velocity Joint Really Constant?

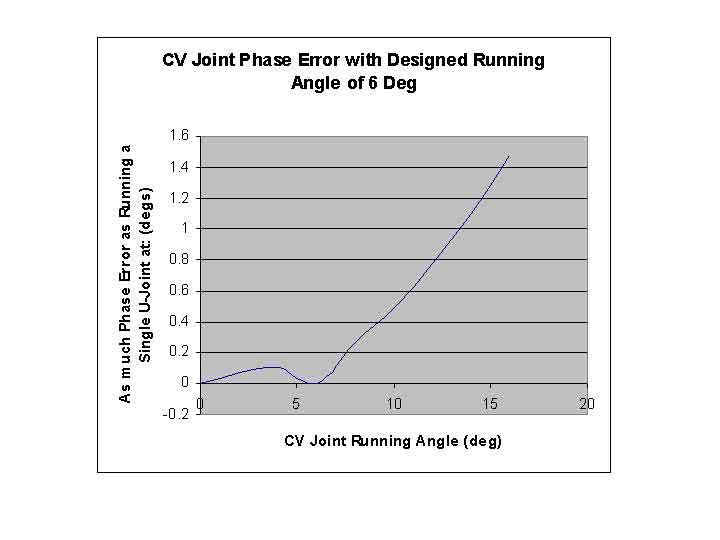

Constant velocity as the name implies means the output should exactly mirror the input. As we know, nothing is perfect, and neither is the CV joint. The CV joint is really designed for perfect phasing at only one running angle. If the joint is ran at other angles, there will be some phase error, but is still very little. My guess is that the Toyota CV joint is ideal at 6 degrees.

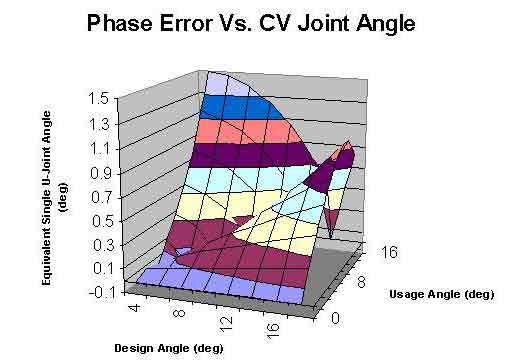

But how much phase error is there if CV joint is ran at other angles? The graph below shows the answer. It assumes a CV joint is designed for running at 6 degrees. This means, the joint would be perfectly constant at 6 degrees with no phase error. The horizontal axis is what angle that the CV joint is going to be used at. The vertical axis is the amount of phase error. It would be meaningless to give a number for the phase error if you can't put that number into perspective. Therefore, the vertical axis is put into persepctive of a single ujoint. That means an error of "1" means your CV joint has as much phase error as if you were using just on regular ujoint running at 1 degree. As seen in the graph below, obviously if the CV joint is used at 6 degrees, there would be no phase error. There is a dip on the graph at 6 degrees. If the same CV joint is used at 14 degrees, then there would be as much error as if you were using a single normal ujoint at 1 degree.

Figure-1

See spreadsheet on calcuation of CV joint (The cells in green can be changed to do "what if" scenario. All other cells are locked and can't be changed)

Prove positive: Page on mathmatical derivation of U-joint

For most rigs, the CV joint error is not significant enough to cause a problem. However, for shor wheel base vehicles that are lifted or with extreme lifts where the CV joint is required to run at high angles. With those angles, the phase error would be more significant. At high angles of around 30 degrees, the error would be as if a single ujoint was running at 5 degrees. A normal stock CV joint would have to be clearanced to run at such angles, or you have to order a custom CV joint.

Let say you do have to run a CV joint at high angle, or you are the perfectionist type who want the driveline to be vibration free at 100mph. Question is if anything can be done about the CV joint phase error. Answer is yes. There are two ways to dealing with CV joint phase error: