3 Ways to Correct Driveline Angles

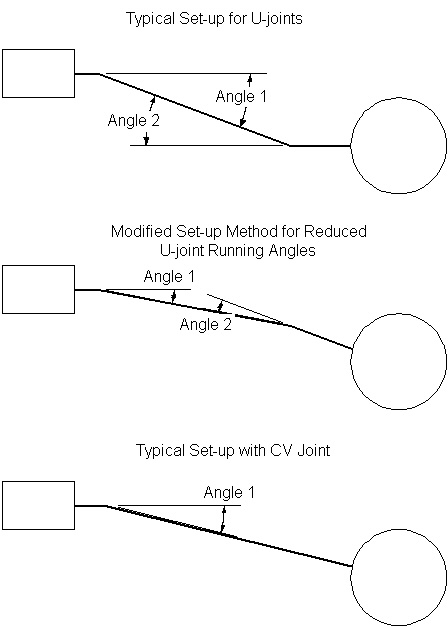

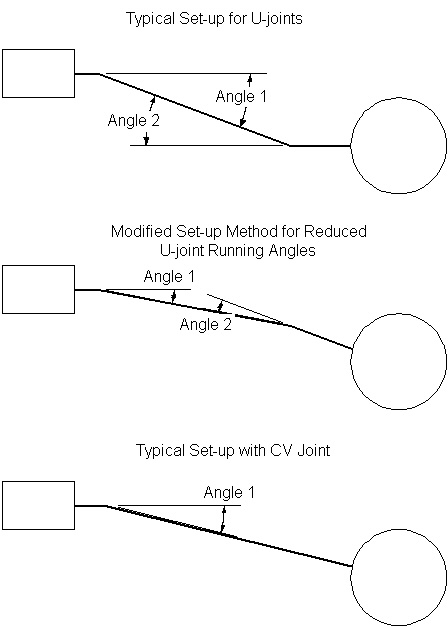

There are three pratical ways to solve dirveline vibrations. They are: u-joint

with opposite angle in the top picture (most common), u-joint with same angle,

middle picture, which is less common and cv-joint on the bottom picture which

is quite common too.

Pros and Cons of each method:

For the Toyota set-up with Old Man Emu Leaf Springs:

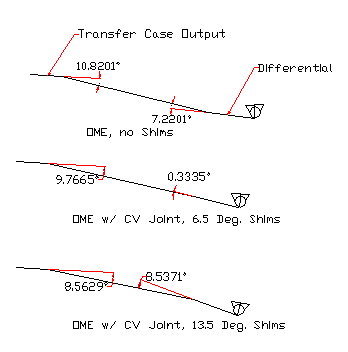

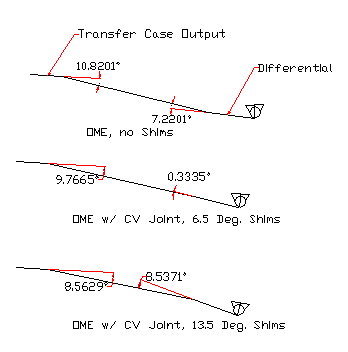

Just by bolting the OME springs on and do nothing, the front u-joint angle

would be 10.5 degree and the rear would be 6.9 degree. This is a problem because

with torque at the wheel, the rear angle would be 6.9 degree - 3 degree(reaction

due to torque load) = 3.9 degree. 10.5 degree in front and 3.9 degree is not

good. That is a 6.6 degrees difference

in bent of the u-joints. This is too much. Some noticable fault is when lifting

the gas pedel going downhill at about 75 to 80mph there is some loud gear

noise. There is gear-wining noise at all slow speeds. If this were a weekend

play truck, this would be all right. As a daily driver, this noise is not

acceptable. There is too much stress on the drivetrain. These gear noise and

whine gets irritating in a long drive. I would not go over 65mph because of

the noise.

I tried rotating the rear axel downward so that the rear and front would

have the same angle. But by rotating the rear axel, the end point of the driveshaft

would be lower also. This increases the front u-joint angle to 12 degree.

The rear would be 12.5 degrees. 12

degrees is a little high for a u-joint angle. Although the output of the driveshaft

is rotating at a constant rate, the shaft itself is speeding up and slowing

down too much. This caused vibration

at high speed. The axel was actually had a .5 degree downward bias from the

transfer case, so when the axel wind up during acceleration, it would be aligned.

This took out more vibration. However, I felt there was still some vibration

in the driveline. I decided to put the heavy short leaf on the spring pack,

which was taken out initially for flexibility, to make the spring the way

it was designed. This final step took out almost all of the vibration.

This is probably because the axel does not rotate as much with the

stiffer spring and cause u-joint misalignments.

However, there is still a persistent vibration that would not go away.

I spent more time trying different spring and shim combination. I tried pointing

the pinion flange at the transfer case with a u-joint at the transfer case.

This helped some, but there was still vibration at high speed especially decelerating

at high speed. My final conclusion is that I need a constant velocity joint

driveshaft similar to the front driveshaft. Using Auto-Cadd, I found that

rotating the axel 4 degrees up would give a 2.8-degree bias on the back u-joint.

With acceleration, that 2.8 degree angle should drop down to 0 hopefully because

of torque on the axel housing during acceleration. I used Auto-Cadd to figure the geometry out because I am tired of

the trial and error method. I got a brand new cv shaft from Inland

Empire Driveline Services. They bought a large batch of Toyota cv shaft

long time ago, and still had a couple left. After paying $480, I installed

the new shaft and a 4-degree shim. That took out all the vibrations

In the decision on CV driveshaft, there are two options. Use a cv-joint on

one end of the driveshaft which is common practice, or to use 2 cv-joints

at both ends of the driveshaft. If I use one cv-joint, I would have to rotate

the axel up so that it point at the transfer case. This would require a 3

or 4 degree shim. This slight amount of rotation should not cause any oil

starvation problems. The other option is to use two cv-joints one at each

end of the driveshaft. This will give a smooth ride no matter what angles

each joint is at. I chose the one cv-joint for cost savings.

After the installation of the CV joint, the ride was as smooth as it

was before the lift. In all, I had

to install and remove the axel many times trying different solution and taking

out leaves to come to an acceptable solution.

The conclusion is that even with a 2.5" lift, a CV driveshaft is absolutely

necessary if you want the truck to be durable. Without the cv shaft, the u-joint

angles are running too high causing shutters and gear noise. For the most

part, since the vibration is torsional, and the engine and transmission is

mounted on rubber mounts, you will not feel anything other than a slight annoyance.

It is easy to ignore that slight vibration. However, that shutter is doing

harm to the gears and bearings throughout the driveline. If you intend to

sell the vehicle after a year or two, or if the vehicle is only used on the

weekend, then there is no point spending the extra money on a cv shaft. However,

if the vehicle is a daily driver, then a cv shaft is a must. That slight vibration

becomes a major annoyance on long trips especially when you know you are destroying

the vehicle as you are driving it. I hate to be faced with a large repair

bill time and time again because the drivetrain was not set up correctly in

the first place. With the CV joint and the 4-degree rotation of the axel,

the ride is absolutely smooth. That is the way that a car should drive in

the first place.

Lots of technical information on u-joint and CV-joint:

On to part 2.

Is

a constant velocity joint really, really constant? It is 99 point nine and

a half percent constant, but not quite...