New Engine

The previous overhaul turned out to be a failure. A year and 15k miles latter, coolant was coming out of the exhaust pipe. Sure sign of a blown gasket. Curiously, the compression was all around 170 psi. There were three choices, either a new truck, rebuild engine, or a new engine. Unfortunately, Toyota don't make a compact 4X4 truck with an efficient 4 cylinder engine anymore. Therefore, keeping the truck was the only way to get what I want. Rebuild engine is cheaper, but new engine would be the most reliable. Some rebuld engines are hit or miss.

New Engine Parts spreadsheet. Total comes to about $3k

OEM and Engnbldr.com New Cylinder Head Casting Comparison

OEM and Engnbldr.com (Rock Products) Head Gasket Comparison

OEM and Engnbldr.com (Rock Products) Timing Component Comparison

OEM and LCEngineering (OSVAT) Valves Comparison

New Engine

Here is the new engine short block from Toyota part number: 11400-35043 $1548.99

Wear Resistant Dry Lube of the Rocker Arms

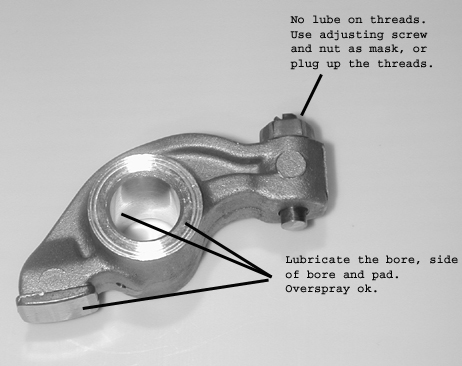

The rocker arm pads looks great, and the bore looks ok. I don't want to spend another $150 or so to replace them all, so I reused them. To make sure they are going to last as long as the rest of the engine, I sent them out for wear resistant coating. Basically a molly sulfide dry lubrication coating.

The website for the dry lube said it will make the part last 2 to 8 times longer. Since the rocker arm already have 130k on them. They probably have another 100k life left. Therefore, if they can be made to last 2x longer, that would be 200k miles more. That makes it as good as a new part, or so it seems. Here are the instructions to the lubrication vendor:

The right picture shows the rocker arm with the black coating of dry film lube on it. The dry film works great for the bore of the rocker arm, but it tend to wear away quickly at the pad.

As it turns out, the oil passage way in the engine was blocked, see below. I ran the engine for a total of about 20 minutes without a drop of oil. When I looked at the rocker arms again, all the dry lube has worn away from the pad. The bore still had the lube on it. However, I am pretty sure the dry lube saved the cam and the rocker arms. In the bore, the dry lube is contained, so did not wear away as fast as the pad. With the constant rubbing of the cam on the pad, I think got rubbed away quickly. With some polishing, I resued the rocker arms and camshaft again.

Metal Backed Timing Guide

For the new engine, I wanted to make sure that the infamous timing chain will not give me any trouble.

I saw from Wade Johnston's web site that you can get an OEM metal backed timing chain guide to replace the failure prone plastic ones. I don't know where he got his part or information, but as far as I know, a 22R use plastic guide just like the 22RE. Is the 21R that use a metal guide.

Preoiling new engine

Here is a cheap way to prelube the engine before starting it. Get a 1/8" BNPT adaptor from McMaster.com and screw it into the oil pressure sender port.. Although any 1/8" NPT would work as long as you just screw it in 1 or two turns. It will be enough to build pressure to prelube the engine. I connected up the fitting to a transmission oil fill pump. At idle, the 22RE engine oil pressure can be as low as 3-5psi, so the transmission oil fill pump was plenty adequate to lubricate the oil. With the valve cover off, I can see oil shooting out of all the rocker arms. While rotating the engine, I could feel the friction go down as oil fill the engine. Gives me a good feeling that there won't be a dry start to ruin my investment.

After all the work was done, I started the engine to warm it up and adjust the valves as well as to retighten the cylinder head bolts. I noticed that the oil pressure gage did not move when the new engine was running. It turns out the oil passageway was blocked in the new engine. See: New engine issue: