Mechanisms on Sand Rover

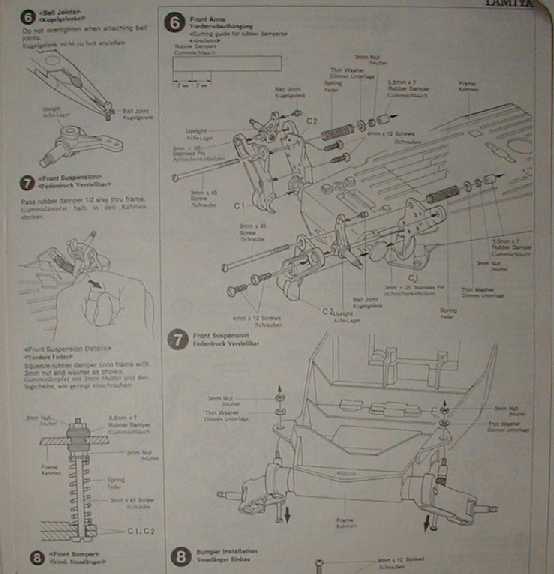

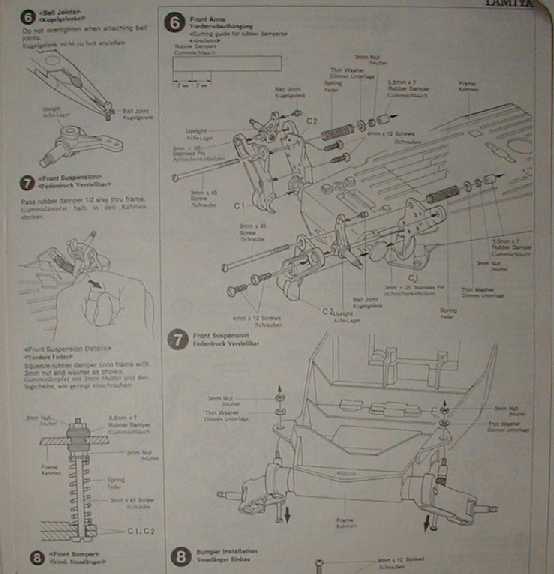

The front suspension arms were two plastic halfs that clamped onto the plastic pivot stub on the tub chassis. There was no damping in the suspension. The arms were suspended with coil springs which is located by a thru bolt that bolts onto the flange in the chassis. There was no room for the bolt to retract upward into the chassis since the Sand Rover body slopes down in the front. Therefore, the thru bolt stays in the same location as the suspension arm cycles upward. The bolt would protrude down from the suspension arms as it cycles upward. The protruting bolts is not a very good design, but it was cheap. With the limited suspension travel, it is unlikely to catch onto anything on the ground.

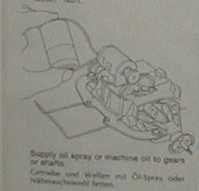

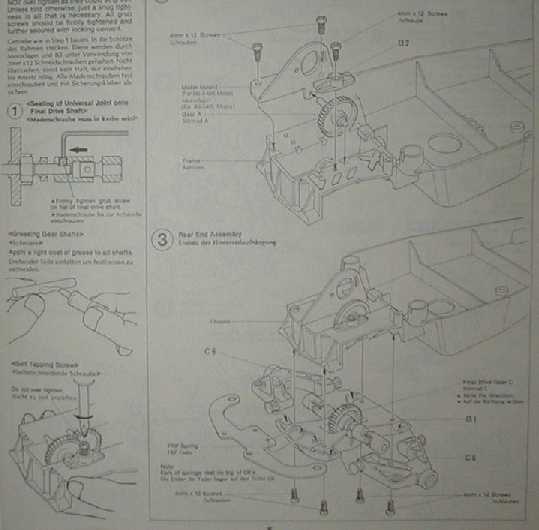

Continuing on with the low cost theme, the rear suspension is made up of a single piece of fiberglass. The flexing of the fiberglass spring probably provided some damping just by the hysterisis property of the material. The shafts that the gears sits in are simply dropped into a small "U" shaped craddle. It is kept from coming back out by a plate and screw that cover the tops of the "U" shaped cradle. Interestingly, the gears are exposed with no attempt to provide a dust cover. This allow for easy lubricant and maintenence but at a cost of faster wear if a more powerful motor was used. It is intersting to note that the rear suspension design is the same type as on the Sand Scorcher / Rough Rider. It is the swing arm design that is also found in the real pre '68 VW buggys. The front suspension is also somewhat similar to the full size VW buggy and Sand Scorcher / Rough Rider with the exception that the Sand Scorcher has a more sophisticated double arm parallelogram design.