Miller Jeep Trail 1/19/02

My work required me to make a trip to the vendor in the LA area. I called my friend Brett in my old company to see if he is available on Sunday before visiting the vendor on Monday. We decided to tackle the Miller Jeep trail. Neither one of us had been on it before. I went on it once on a motorcycle. It was tough on a motorcycle, but I figure, it would be easier in a car. Brett got a 6" lift on his full size Bronco back in November, and had installed an ARB differential. It was not hooked up yet for the trip though. He also has a CO2 Power tank to air up the tires. I booked a 6:50 am flight. My fiancee took me to the airport at 5:30 am. The flight got delayed until 9:00. We finally got to he Lockwood trail head at around 1:00. It was a little late, but it might still be ok.

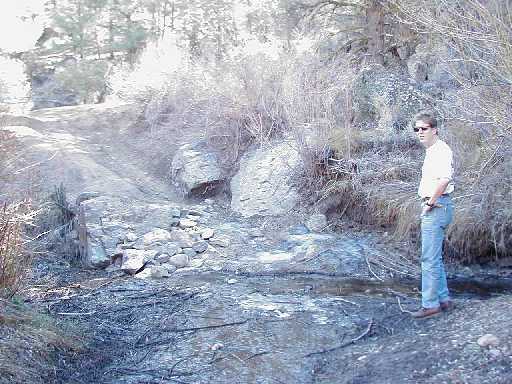

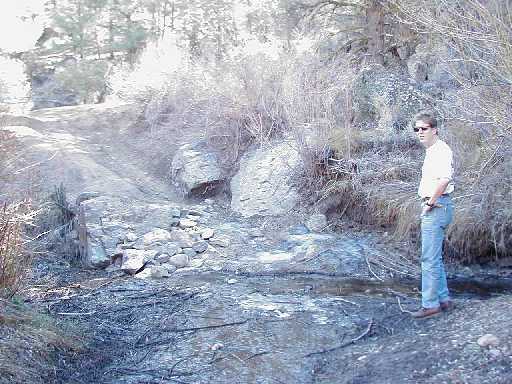

We took a look at the Yellow Jacket Canyon. We stopped went we got to a stone

we call the Rosette Stone. It was a boulder in the side of the trail that made

it very difficult. We did not go on it, but continued on the Lockwood trail

towards Miller Jeep trail.

The first part of the trail was up a steep grade. To make it worst, there was a bolder in the middle of it that made you squeeze between it and the wall. It was a challenge with the Bronco.

After the grade, it took some skill to maneuver the big Bronco through the trees. Brett had done that part of the trail several times already. It was three hills before we would get to the base of the Miller trail.

The first sign of trouble was when the Bronco stalled on a steep downhill. Having an engine cutout in a full size Bronco in a steep hill with no power brake and steering is a hairy situation. Good thing the brake vacuum booster held the vacuum, and Brett started the engine again. On the downhill switch backs, the engine stumbled several times. Each time was quite frightening. By the time we got to the base of the miller trail, the engine was barely running. Brett removed power to the computer to reset it. That seemed to work for a while as we were going back. At the base of the Miller trail, a group of truck was about to tackle the trail. We asked them how hard the trail would be. They said it was nothing like we have gone through yet. We wisely decided to turn around given that the truck was not running right.

The Bronco has an infamous weak tie-rod. The larger tires made it worst. Some where along the trail, the rod was slightly bent. Brett turned the rod end to do an informal alignment by eye. It worked quite well.

Coming back, the setting sun was right in our eyes. A small error in turning caused the left wheel to hit a protruding rock, which cut the sidewall.

Rather than changing the tire, we kept adding air to the tire. Thank goodness for Brett's CO2 bottle. It was really fast to fill those 36" tires. The hose went stiff the first time we filled the tires because the CO2 liquid got into the hose. He remembered after that to hold the bottle upright when filling the tires. The cold CO2 made the hose so brittle that it almost cracked just by flexing it. Is no fun to crack the hose at that point. It was miles from no where with no one around, and a setting sun. That was the only hose we had. We carefully let it thawed so it becomes flexible again, and continued.

The last part of the trail was the most difficult. We had to squeeze between a large rock and the side of the hill while going downhill, and the engine was barely running at this time. We had to back up and re-approach that part to get it right. The engine was ready to die when the rear wheel had to climb the rock. Brett punched the gas pedal, and barely got over the rock then down the steep hill. It was a leap of faith since once he got to the hill part, if the engine died, he would have lost power brake to stop the truck at the bottom.

We had slashed a new tires, bent tie rod, an engine that was not working properly, and we were not able to finish the Miller trail. It made for a frustrating day.

To our surprise, when we got onto the pavement, the engine ran fine. Go figure...

Latter, Brett found out that the problem was with the fuel filter. He already changed the filter before. Evidently, on Ford vehicles, it is recommended that the filter be changed every year. When the filter gets clogged up, pressure would build up behind the filter and burn out the fuel pump as well. After changing the filter, the truck still ran poorly, and the fuel pressure was less than what it should have been. The fuel pump also did not sound like it use to. After changine the fuel pump as well, it was all well with the truck.