22RE Engine Half Rebuild

The 22RE engine in the 4Runner had a hard life. It was used to tow a 2000lbs.

trailer for 60k. The original owner said he never went on hills, but that is

still quite a bit of work. I drove it on and off-road until 115k.

There were several things that bothered me about the engine.

- Used quart of oil every 500-600 miles.

- Compression around 135-170psi.

- #1 plug was white hot, with broken insulator. Rest of the plugs were hot

too, but not as bad.

- Lack of power, and lazy acceleration

- Runs very hot eventhough the temp. gauge shows it to be in the middle. Rubber

hose were getting brittle due to the heat.

- Timing chain rattle at start-up that last for several seconds until you

gun the engine.

- Hesitation during idling as if about to die, then catches on again.

- Whisle noise coming from the exhaust every now and then

- Poor gas mileage for 30" tires and 2.5" lift. 18mpg to 20mpg

Here are some of the things that I did to the engine before the engine refresh:

- New off-set oil seal in the front to cure the oil leak. Engine still use

oil.

- Paid to have injectors cleaned using the injector cleaning machine. The

idle got somewhat better, but still not as smooth as it can be.

- Removed all 4 sparkplugs, and poured transmission oil into each cylinder,

then waited for an hour or so. Every now and then, I turned the cranks a little

to work the rings. The was suppose to remove carbon deposit from the rings.

Afterward, I had to drive around the block in the middle of the night because

of the smoke coming out of the tail pipe. As I drove around the block twice

the smoke lingered so thick that I could not see where I was going! This made

the most improvement on the engine. Compression went from 130-140psi to 170-185psi.

The truck seemed to have some more pickup during acceleration.

The truck had relatively low mileage, so I was going to leave the engine alone

even though it was an irritant. One day coming back from work, the engine pinged

while going up a sligth incline, and smoke came out of the tailpipe. Pulling

the plugs, the #3 and #4 cylinder had oil on the plug while the #1 was white

hot as usual. The compression was still 175-180psi, so that was quite good.

It was burning oil, so I decided to do an engine teardown. I don't want to spend

the money to do a rebuild. My job was not stable as the company was downsizing.

Wife was pregnant, so spending two thousand for a rebuild engine was not an

option. I just want spend a one or two hundred bucks to keep it in good running

condition for another 100k or so before I pour in the money for a complete quality

rebuild. Hopefully, economy would improve by then. Here is what I did and found.

- One exhaust nut was loose. This must have made the whistle noise. Due to

the loose nut, the exhaust manifold got warped. $40 for a sanding job fixed

that. The leaking exhaust would have sucked air into the manifold. That could

have thrown off the O2 sensor reading, and given the wrong mixture information

to the engine computer.

- Rubber isolators on the injectors were badly deteriorated. Injectors looked

fine. The deteriorated isolators probably caused air leakage. I sent them

out to Cruzin Performance

in Minnisota. That to info provided by Roger Brown's website.They were only

2% off of each other. After cleaning, they were 1% off. For $68 all together

including shipping, they gave me new orings and rubber isolators for no extra

charge. Those alone would have costed $36 at the dealer. This outfit is highly

recommended! The deteriorated isolators could have caused the lean mixture

for #1 cylinder, and maybe caused the hot condition.

To my surprise, the infamouse

guides were hardly worn at all. The driver side had no measurable wear. The

passenger side had .002" of wear. Way below spec. I was going to replace

them with another set of plastic guides. Metal ones were too expensive. Plus,

if it ain't broken... When I put the new set of guides in, I noticed something.

The old ones had lots of slop in the shoulder screw. You could feel the guides

move when you wiggle them. The new ones due to tolerance, was compressed by

the shoulder screw, and could not move. The new guides were just about .001"

thicker than the length of the shoulder portion of the screw, so it could

not move. The movement was probably there for CTE (Coeficient of Thermal Differential)

difference between plastic and the metal engine when it heats up. If the guides

could no move freely, then there could be lots of stress on the plastic. That

could be the reason why guides fail. Is not from wear, but from CTE which

cause fatigue failure. Anyway, base on the amount of wear so far, I am confident

these guides will last another 100k miles.

To my surprise, the infamouse

guides were hardly worn at all. The driver side had no measurable wear. The

passenger side had .002" of wear. Way below spec. I was going to replace

them with another set of plastic guides. Metal ones were too expensive. Plus,

if it ain't broken... When I put the new set of guides in, I noticed something.

The old ones had lots of slop in the shoulder screw. You could feel the guides

move when you wiggle them. The new ones due to tolerance, was compressed by

the shoulder screw, and could not move. The new guides were just about .001"

thicker than the length of the shoulder portion of the screw, so it could

not move. The movement was probably there for CTE (Coeficient of Thermal Differential)

difference between plastic and the metal engine when it heats up. If the guides

could no move freely, then there could be lots of stress on the plastic. That

could be the reason why guides fail. Is not from wear, but from CTE which

cause fatigue failure. Anyway, base on the amount of wear so far, I am confident

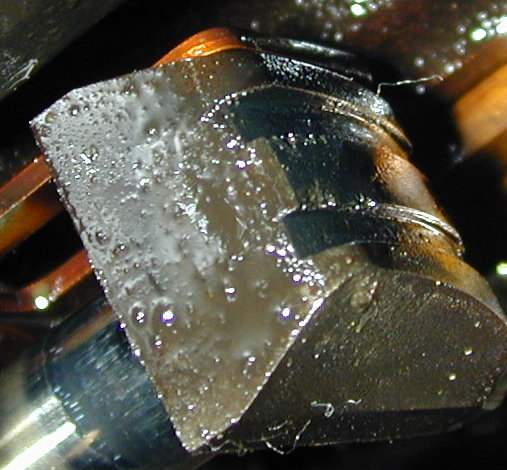

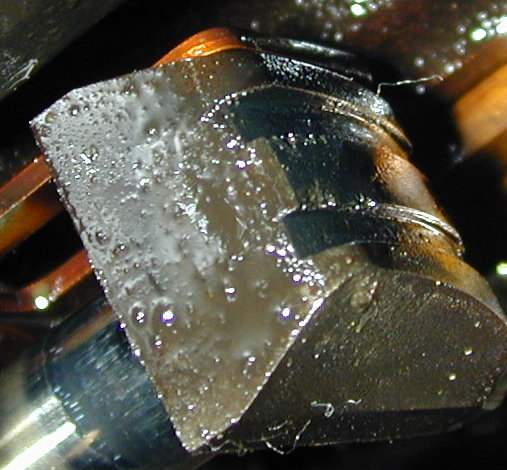

these guides will last another 100k miles. The wear on the tensioner

was another story. There were deep grooves on the plastic rub piece of the

tensioner. That had to be replaced.

The wear on the tensioner

was another story. There were deep grooves on the plastic rub piece of the

tensioner. That had to be replaced. The piston came out with

no problem. No need for a ridge reamer. There was quite a bit of carbon deposits.

Soaking in WD40 per Roger Brown's web site worked wonders. I had a gallon

can of WD40.

The piston came out with

no problem. No need for a ridge reamer. There was quite a bit of carbon deposits.

Soaking in WD40 per Roger Brown's web site worked wonders. I had a gallon

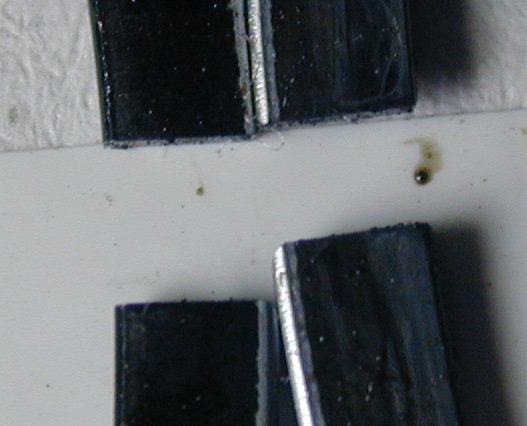

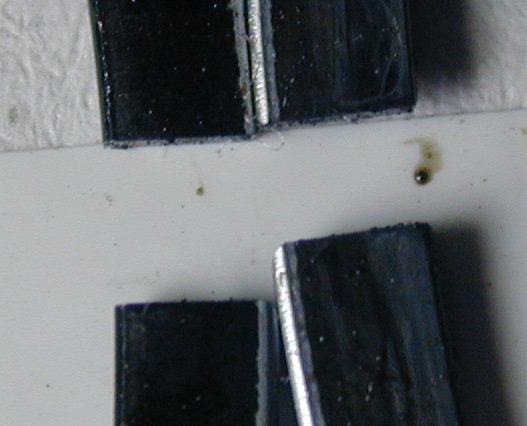

can of WD40. The compression rings on the

pistons were fine, but the oil control ring showed relaxation. The left ring

is the replacement one. The right one is the original. Assume tension on ring

is proportional to end gap, the original rings would have lost about a third

of the tension. This could be the cause of oil usage during acceleration.

Since I am only replacing the oil control rings, and not the compression rings,

the walls of the cylinder should not need to be honed. There should not be

much pressure on the oil control ring anyway, so there should not be need

for breaking in. I was hesitant to replace the main compression ring due to

the difficulty of breaking in chrome rings. Per enginbldr.com, moly and chrome

rings are difficult to break-in. You should use cast iron ring if you are

not boring out the cylinder. However, cast iron ring also wear faster than

the chrome rings. For maximum durability, I figure, using the original rings

should be the best way to go especially the compression is already 175psi.

The compression rings on the

pistons were fine, but the oil control ring showed relaxation. The left ring

is the replacement one. The right one is the original. Assume tension on ring

is proportional to end gap, the original rings would have lost about a third

of the tension. This could be the cause of oil usage during acceleration.

Since I am only replacing the oil control rings, and not the compression rings,

the walls of the cylinder should not need to be honed. There should not be

much pressure on the oil control ring anyway, so there should not be need

for breaking in. I was hesitant to replace the main compression ring due to

the difficulty of breaking in chrome rings. Per enginbldr.com, moly and chrome

rings are difficult to break-in. You should use cast iron ring if you are

not boring out the cylinder. However, cast iron ring also wear faster than

the chrome rings. For maximum durability, I figure, using the original rings

should be the best way to go especially the compression is already 175psi. The cylinder looked great.

There were specks of rust on the #3 cylinder. There was no ridge on the top.

You could still see the hatch pattern on the wall. The cylinder are almost

still new!

The cylinder looked great.

There were specks of rust on the #3 cylinder. There was no ridge on the top.

You could still see the hatch pattern on the wall. The cylinder are almost

still new! The intake valves were fine,

but the exhaust valve looked marginal. 4 new exhaust valves were put n. The

seat looked fine, so I just lapped the valves in. There was almost no detectable

movement of the valve in the guide. The guides were in great shape. Some Viton

valve seals from Fel-Pro finished the valve job. The original seals were quite

hard due to the high temperature.

The intake valves were fine,

but the exhaust valve looked marginal. 4 new exhaust valves were put n. The

seat looked fine, so I just lapped the valves in. There was almost no detectable

movement of the valve in the guide. The guides were in great shape. Some Viton

valve seals from Fel-Pro finished the valve job. The original seals were quite

hard due to the high temperature.- To cure the high temperature issue, I drilled a 3/32 hole on the thermostat.

This is to allow hot coolant to pass thru the thermostat, and open the valve

faster. I also found piece of foam blocking the lower quarter of the radiator

blocking the air entrance below the bumper.. It was neatly cut and placed

there. I don't think Toyota would have done such a thing. I move the foam

lower so that it would not be blocking the radiator so much. That could have

caused the high temperature in the engine compartment.

- Hylomar was used on all gasket surface on installation. This will make sure

there is a good seal on all the mating surfaces, and also make it easier to

clean up the gasket at the next repair.

- Torqued the intake and exhaust bolts, then waited an hour or so for gasket

the settle, then re-torqued. The gasket compresses after the first half an

hour. The bolts then becomes a little loose again.

- New water pump was put in. The original looked pretty good. From experiance,

the alternators on Japaneese cars are pretty durable, but the water pump is

the weak link.

- Adjusted the valves to .007" intake, and .011" exhaust cold. After

first start-up, the valves were noisey, so I had to adjust them hot again

to spec.

- Adjusted the throttle position sensor,TPS, per Roger Brown's site. When

you adjust the throttle stop position, you pretty much have to adjust the

TPS as well.

Results of the engine work:

- Used quart of oil every 500-600 miles.---->Now: estimated to use a quart

every thousand miles.

- Compression around 135-170psi.---------> Now around 150-160psi.

- #1 plug was white hot, with broken insulator. Rest of the plugs were hot

too, but not as bad.------> Plug color nice tan.

- Lack of power, and lazy acceleration-----> Now definitely more power.

Now I could do 70mph up the same hill.

- Runs very hot eventhough the temp. gauge shows it to be in the middle. Rubber

hose were getting brittle due to the heat.----> Appears to run cooler.

That could be psychological though.

- Timing chain rattle at start-up that last for several seconds until you

gun the engine.-------> Now: The tensioner must have been the problem.

No more rattling sound at startup. Rattling came back slightly after several

thousand miles. Oil was not changed for a long time. After an oil change,

is fine now.

- Hesitation during idling as if about to die, then catches on again.------->

Now: Engine is very smooth running. No hesitation.

- Whisle noise coming from the exhaust every now and then----> Now: Aftet

the engine work, exhaust nuts kept loosening. Finally, I

used Stage-8 fasteners to solve the problem.

- Poor gas mileage for 30" tires and 2.5" lift. 21mpg average----->

Now: First run got 16.5mpg, second tank was 18mpg. Third tank was 19.9 mpg.

Mileage got better as the computer learned. Highway/City driving is about

21mpg. City only driving is 16.5mpg. Not much change from before. Guess 21mpg

is about as much as I can expect.

To my surprise, the infamouse

guides were hardly worn at all. The driver side had no measurable wear. The

passenger side had .002" of wear. Way below spec. I was going to replace

them with another set of plastic guides. Metal ones were too expensive. Plus,

if it ain't broken... When I put the new set of guides in, I noticed something.

The old ones had lots of slop in the shoulder screw. You could feel the guides

move when you wiggle them. The new ones due to tolerance, was compressed by

the shoulder screw, and could not move. The new guides were just about .001"

thicker than the length of the shoulder portion of the screw, so it could

not move. The movement was probably there for CTE (Coeficient of Thermal Differential)

difference between plastic and the metal engine when it heats up. If the guides

could no move freely, then there could be lots of stress on the plastic. That

could be the reason why guides fail. Is not from wear, but from CTE which

cause fatigue failure. Anyway, base on the amount of wear so far, I am confident

these guides will last another 100k miles.

To my surprise, the infamouse

guides were hardly worn at all. The driver side had no measurable wear. The

passenger side had .002" of wear. Way below spec. I was going to replace

them with another set of plastic guides. Metal ones were too expensive. Plus,

if it ain't broken... When I put the new set of guides in, I noticed something.

The old ones had lots of slop in the shoulder screw. You could feel the guides

move when you wiggle them. The new ones due to tolerance, was compressed by

the shoulder screw, and could not move. The new guides were just about .001"

thicker than the length of the shoulder portion of the screw, so it could

not move. The movement was probably there for CTE (Coeficient of Thermal Differential)

difference between plastic and the metal engine when it heats up. If the guides

could no move freely, then there could be lots of stress on the plastic. That

could be the reason why guides fail. Is not from wear, but from CTE which

cause fatigue failure. Anyway, base on the amount of wear so far, I am confident

these guides will last another 100k miles. The wear on the tensioner

was another story. There were deep grooves on the plastic rub piece of the

tensioner. That had to be replaced.

The wear on the tensioner

was another story. There were deep grooves on the plastic rub piece of the

tensioner. That had to be replaced. The piston came out with

no problem. No need for a ridge reamer. There was quite a bit of carbon deposits.

Soaking in WD40 per Roger Brown's web site worked wonders. I had a gallon

can of WD40.

The piston came out with

no problem. No need for a ridge reamer. There was quite a bit of carbon deposits.

Soaking in WD40 per Roger Brown's web site worked wonders. I had a gallon

can of WD40. The compression rings on the

pistons were fine, but the oil control ring showed relaxation. The left ring

is the replacement one. The right one is the original. Assume tension on ring

is proportional to end gap, the original rings would have lost about a third

of the tension. This could be the cause of oil usage during acceleration.

Since I am only replacing the oil control rings, and not the compression rings,

the walls of the cylinder should not need to be honed. There should not be

much pressure on the oil control ring anyway, so there should not be need

for breaking in. I was hesitant to replace the main compression ring due to

the difficulty of breaking in chrome rings. Per enginbldr.com, moly and chrome

rings are difficult to break-in. You should use cast iron ring if you are

not boring out the cylinder. However, cast iron ring also wear faster than

the chrome rings. For maximum durability, I figure, using the original rings

should be the best way to go especially the compression is already 175psi.

The compression rings on the

pistons were fine, but the oil control ring showed relaxation. The left ring

is the replacement one. The right one is the original. Assume tension on ring

is proportional to end gap, the original rings would have lost about a third

of the tension. This could be the cause of oil usage during acceleration.

Since I am only replacing the oil control rings, and not the compression rings,

the walls of the cylinder should not need to be honed. There should not be

much pressure on the oil control ring anyway, so there should not be need

for breaking in. I was hesitant to replace the main compression ring due to

the difficulty of breaking in chrome rings. Per enginbldr.com, moly and chrome

rings are difficult to break-in. You should use cast iron ring if you are

not boring out the cylinder. However, cast iron ring also wear faster than

the chrome rings. For maximum durability, I figure, using the original rings

should be the best way to go especially the compression is already 175psi. The cylinder looked great.

There were specks of rust on the #3 cylinder. There was no ridge on the top.

You could still see the hatch pattern on the wall. The cylinder are almost

still new!

The cylinder looked great.

There were specks of rust on the #3 cylinder. There was no ridge on the top.

You could still see the hatch pattern on the wall. The cylinder are almost

still new! The intake valves were fine,

but the exhaust valve looked marginal. 4 new exhaust valves were put n. The

seat looked fine, so I just lapped the valves in. There was almost no detectable

movement of the valve in the guide. The guides were in great shape. Some Viton

valve seals from Fel-Pro finished the valve job. The original seals were quite

hard due to the high temperature.

The intake valves were fine,

but the exhaust valve looked marginal. 4 new exhaust valves were put n. The

seat looked fine, so I just lapped the valves in. There was almost no detectable

movement of the valve in the guide. The guides were in great shape. Some Viton

valve seals from Fel-Pro finished the valve job. The original seals were quite

hard due to the high temperature.